GAMMA FAILSAFE MEMBRANE SHOCK ABSORBERS

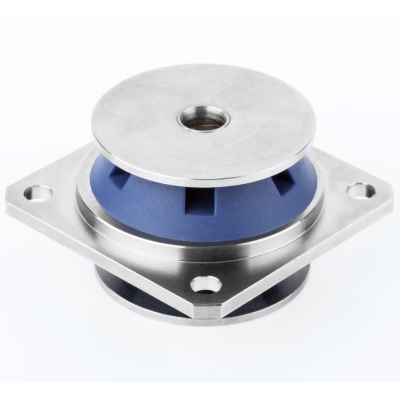

This family of shock absorbers is the result of GAMMA’s early development of anti-vibration systems; they form an essential part of our standard program.

- Operating temperatures: -55° to 150 °C

- High resistance to mechanical fatigue

- Vibration levels up to +/-3 mm

- Frequency from 8Hz

EXAMPLES OF APPLICATIONS

These shock absorbers are also used to create suspensions in fields more specific to navigation and optronic systems.

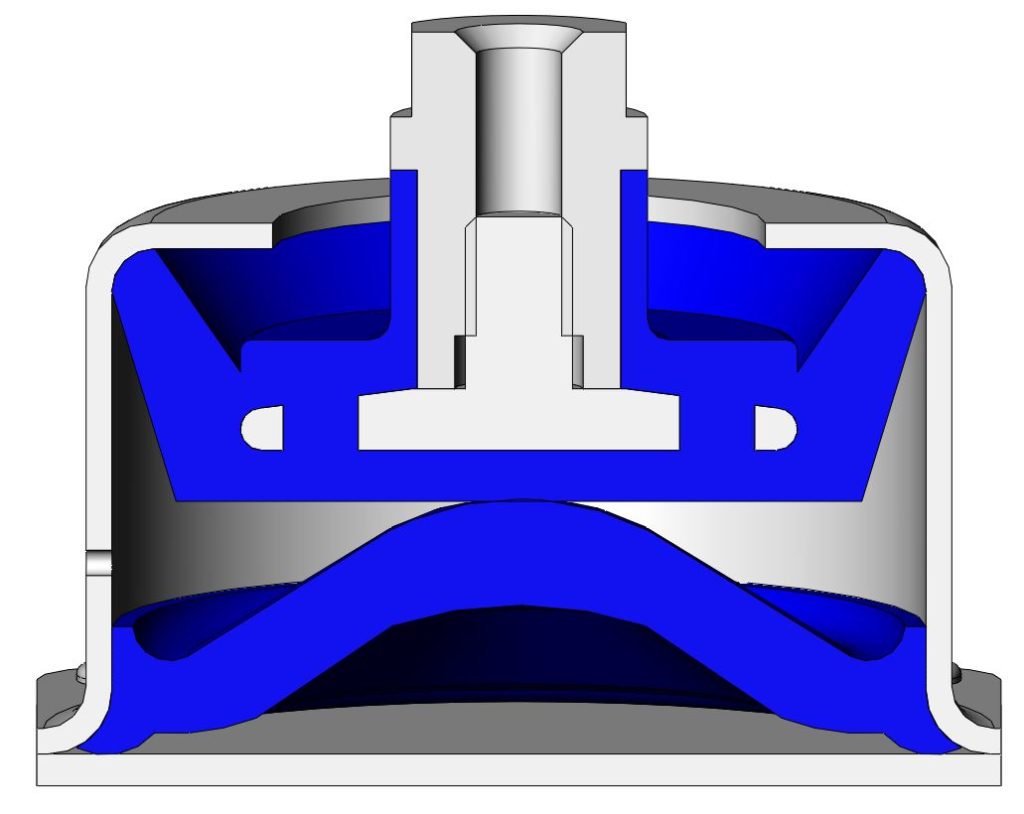

The principle behind these shock absorbers is to combine the intrinsic characteristics of our high-mechanical-performance elastomers with their ability to deform under stress.

This combination is used to achieve high working rates in relatively small volumes, effectively withstanding vibration levels of up to +/-3 mm with frequency ranges from 8 Hz and extended loading ranges. Another objective is to achieve high resistance to mechanical fatigue, with operational lifetimes of several million cycles, representing thousands of hours of operation.

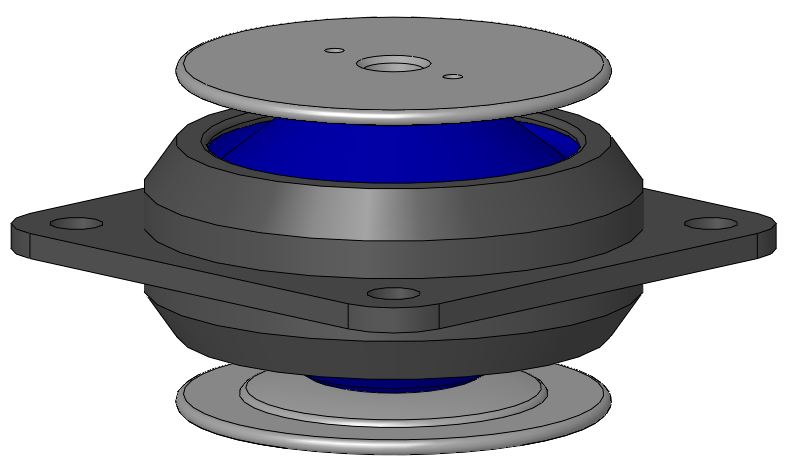

REFERENCE VERSIONS AND LAYOUTS OF SAFETY-TYPE DIAPHRAGM SHOCK ABSORBERS

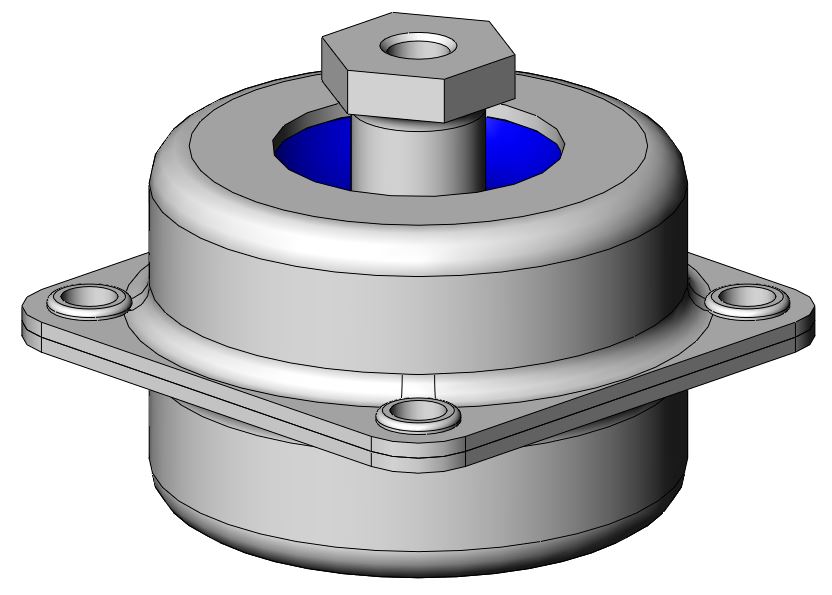

In this configuration, there are 3 possible variations with 2 possible layouts:

- housing with base fixing

- housing with centre fixing

- flange with central fixing

This technology allows the shock absorbers to be used in all loading conditions with virtually the same axial stiffness vs. radial stiffness behaviour, with damping coefficients that can reach very low values. The performance achieved is superior to that of a conventional cylindrical shock absorber, which exploits only the intrinsic characteristics of the elastomers used. This is achieved through the use of friction damping, which can be optimised in the following configuration (see diagram) with a load applied in compression.

In some cases, this characteristic can be made even more pronounced by combining it with viscous-type damping for GDL family products.

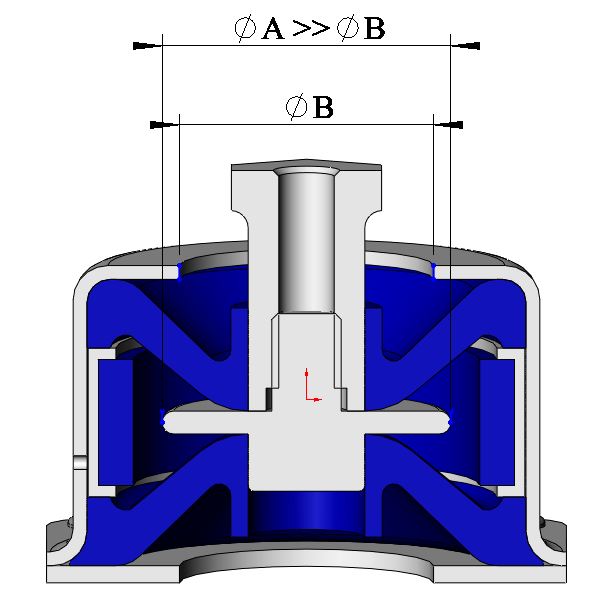

The judicious dimensioning of the metal parts of these shock absorbers, by the choice of diameters represented in the visual below, gives them their safety aspect. In the event of an incident destroying the elastomer, the suspended mass will remain attached and people will be protected.

This characteristic limits the free sway space of the shock absorbers. They are therefore used mainly for their excellent vibration characteristics, their ability to filter medium shocks and to withstand severe shocks without destruction.

For a large number of applications, the anti-vibration element is mainly developed as standard in silicone. It covers an operating temperature range from -55°C to +150°C. The use of specific elastomers enables it to withstand harsh external environments such as fuels and hydraulic fluids for engine applications.

Do you have a project?

Don’t hesitate to discuss your project with us in complete confidentiality. We are ready to work with you to develop your ideal anti-vibration solution.